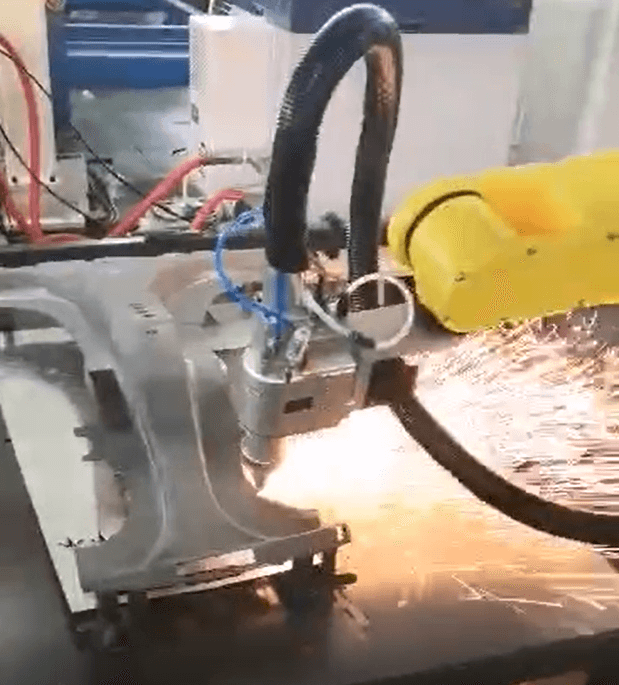

Laser metal welding

Laser welding technology is the most modern way of joining various steels and alloys. Its main advantage is obtaining a very precise geometrically and mechanically strong seam, which has a pleasant appearance and often does not need post-processing.